Can you tell us how Carpentry & Boat Building Services began and what inspired you to create the company back in 2007?

I began CABBS after serving 5 years onboard a 65m wooden sailing yacht as the head carpenter, and I decided to start CABBS as I saw a massive void of high-end skill on the island at the time, and felt that my skill set might be suitable. My first child was two years old by this stage, and I also did not wish to go away and leave my family for months at a time. Coupled with this, the sideline freelance job I had was willing to contract me full-time, so the stars aligned, and I took the plunge.

What was your initial vision for CABBS, and how has it evolved over the years?

My vision for CABBS now is the same as it was in the very beginning, and it is a super simple one: to deliver the highest quality craftsmanship, the best possible service, and, as much as possible, give clients what they want. Happy clientele means return clientele. We are playing the long game and are not here to make a quick buck and leave clients stranded, so to speak

You’ve been in Palma de Mallorca since the start—what makes this location such an ideal base for your work in the superyacht industry?

I fell into this industry purely by chance, not even knowing where Mallorca was when I first started on the boats. I have come to learn that Mallorca has grown into the central hub of the Mediterranean superyacht scene for a number of reasons. Its location is good to stop at on the way in and on the way out of the Med. The weather is stable and reliable as far as the weather goes, so it makes a good, safe place for the yachts to winter over. Originally, it was extremely cost-effective as the cost of living and getting work done was extremely cheap. Unfortunately, this has changed, but as the island’s industry has grown, so has the infrastructure and support for the boats. So there is an extremely good base of professionals here dedicated to the boats. Also, now with STP shipyard having one of the biggest haul-out travel lifts in the world, it means even more boats can get work done here. So this creates plenty of demand.

CABBS has earned a reputation for precision and quality. How do you define craftsmanship in the context of modern yacht building and restoration?

I think that’s relatively simple: attention to detail and a willingness to go the extra mile, so the results speak for themselves. Cutting corners shouldn’t be an option, and the craftsmen need to take pride in their work to achieve the finish and results these impressive boats deserve. I feel that with what we do, which is a lot of modification work and minor refits, one of the most satisfying comments that can be made is when the client says that they cannot see where we were working, as we have blended in our work so well.

What kind of skills and techniques are required to work at the level CABBS operates, particularly when combining traditional woodworking with contemporary yacht design?

Basically, our tradesmen are skilled, detail-oriented woodworkers. Traditionally, in the English classifications, you would call them Yacht Joiners. But I like to judge people who come to work for CABBS by what they can create with their hands, not what titles or qualifications they may have. We can see very quickly whether a person has what it takes to do the job, or at least can be trained to do the work.

I think some of the traits I look for in people are an open mind, an ability to absorb new information quickly and pivot, an ability to handle stress and still smile, pride in their work, and, again, attention to detail. As far as techniques go, general quality woodworking techniques are very similar the world over, so this is kind of expected. Experience working with solid wood and veneers is a definite advantage. Most other specialised techniques we may have, we can teach pretty quickly to the right people. Of course, if we are looking for juniors, we don’t expect this level of experience, but the willingness to learn and work is key for these junior positions.

The range of services you offer is impressive—from teak decking to full interior refits. Which types of projects do you personally find most rewarding?

I personally am a New Zealand-trained wooden boat builder, so my first love is to start with an empty workshop and build a boat to completion and watch it sail away. Unfortunately, this section of the boating industry is very small here in Mallorca, so that’s why I went down the superyacht path due to the sheer number of boats here. When I first started, I basically did everything and anything, but as time went on, I dedicated myself more to interior alterations, refits, and bespoke furniture, as I find this more fulfilling and suited to my way of thinking than teak decking. I found there was more competition in the teak deck industry as well, so I chose to specialise more in the interiors.

You mention the “vast skill base” of your team as a core strength. How do you go about building and maintaining such a high level of expertise across so many disciplines?

It sounds like a simple enough idea: hire the right people. Experienced tradesmen who have been around and gained expertise by simply being a good tradesman and learning as much as they can. Then, getting them to train younger workers to pass on as much of their information as possible. It sounds simple, but these days hiring skilled tradesmen is not as easy as it once was.

Can you describe your typical process when taking on a new project—from initial client discussions to completion?

Initially, I will get approached by a potential client, most times from a recommendation from a friend of theirs. They will email, call, or WhatsApp me. After a brief explanation, we would organise a time to meet on board, and the work will be shown to me and discussed. Usually, from here, measurements can be taken, and I can then produce an estimate. If all goes well, it is accepted, and timing and details are worked out. A deposit invoice is issued, and on payment, materials are ordered, and work commences.

During the work, we are in close communication with our clients, and any major decision that needs to be made is discussed with them first, problems are resolved, and plans are most likely tweaked as we go. If the project is large enough, there will be stage payments; if not, a final invoice is issued when the job is finished and approved, and as long as the invoice is paid, everyone is usually happy.

How do you balance the technical precision of yacht carpentry with the creative design elements that make each project unique?

Well, I guess to be honest, there is less creative design in what we do, as any major design elements are usually undertaken by the client or their designer, so in this case, we do as instructed.

Otherwise, we generally follow other people’s work, making things fit into an existing design, and copying the style and methods used by the original builders. We do, of course, need a good eye for colour and shape, and a good spatial awareness to ensure our solutions to the problem are practical as well as in line with the existing design. We do struggle at times sourcing materials that match, as every boat is different and when you are trying to match different woods and different finishes and meet different clients’ expectations, it does get a bit tricky. We do the best we can, take pride in our work, and things usually work out.

Yacht refits and restorations can be complex undertakings. What are some of the biggest challenges your team faces, and how do you overcome them?

I’d say our biggest challenge is time restrictions. The boats in this industry are bound not only by the weather but also by the fact that a lot of them are chartered, so there are deadlines that just can’t be missed. This can be tricky as boats are renowned for unforeseen issues cropping up and throwing schedules out the window. For us, we overcome these issues usually by planning as carefully as we can in the beginning and making sure we are not dragging our feet, as any time lost at the beginning can be costly at the end. When we need to, we have a range of carpenters here we fall back on to help us through, as we help them at times. It’s a small island, and we all have to live here together, so without people you can call on, it gets very hard.

Availability of materials is also a big one. Being on an island with a relatively small high-end carpentry industry, finding the right products can be very difficult. We normally end up sourcing from either mainland Spain or the rest of Europe. Sometimes, even as far afield as the USA or Australia, depending on what we need, this then adds complications to the time issue as mentioned before… It keeps us on our toes, that’s for sure.

Are there any standout projects in CABBS’ history that you’re particularly proud of—ones that really capture what the company is about?

Most of the ones that stand out, we have put up on our website. We did a subcontracted job in 2016 in Barcelona, where we were up against the clock quite badly. We were subcontracted to another company from Palma that really needed a hand, so we went over there to help them out. Big hours, and most of the other companies didn’t think we would finish, but we did, and the owner was happy. The work turned out lovely, and I was super proud of how my team came together to get a particularly difficult job over the line.

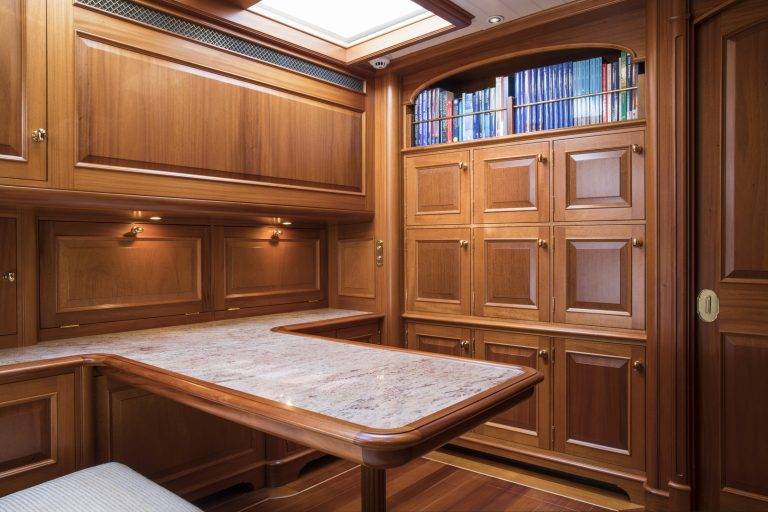

Another job I am proud of is an office modification we did on a modern classic sailing yacht from one of the most prestigious yacht builders in northern Europe. We needed to match a new table, shelves and two custom-made temperature-controlled wine drawers into some high-quality joinery. Looking at the photos, it’s very difficult to see where the original boat stops and our work begins. Just what I want to see.

The superyacht industry has changed a lot in the last two decades. How have client expectations and project demands evolved during that time?

This is an interesting one; each winter season seems to get smaller. It seems as if the yachts wish to use their boats longer in the summer/ autumn and start again earlier in the spring, compressing each winter period.

This, coupled with the slow dilution of the deeply experienced crew due to the sheer number of vessels that require crew, has now led to a higher occurrence of unrealistic expectations in either timing or cost.

I also think in many aspects the demands have increased in many of the superyacht sectors, I’d say electrics and engineering especially with the rapidly advancing technology many yachts systems these days are very dated so the demands for engineers and electrical engineers to not only stay updated with the modern tech and methods they are still expected to be able service and maintain systems that could be 30 years old or more.

How do modern technologies and materials influence your work today compared to when you started?

Where I did my apprenticeship, it was a semi-traditional woodworking yard. Wooden boats, wooden joinery, and a lot of manual fabricating. Now, with the advent of CNC cutting in so many forms, routing, laser, waterjet, plasma, coupled with 3d printing, the possibilities are mind-blowing. We have incorporated CNC machining into our facilities, and for projects where we can use it, it has revolutionised the way we think. Work that once would take months can be done in weeks. For me, it is amazing, and I am constantly looking for ways we can incorporate this technology into how we operate. The speed and accuracy increases are incredible.

CABBS was founded on the idea of combining craftsmanship with exceptional service. How do you ensure that ethos continues to guide the business today?

I think a key factor is nurturing this idea with the team and making sure the people around you share this mindset. I need people who are willing to do their best, take pride in their work and care about what the client thinks. I feel extremely privileged that my team are with me in this. We have found that it just happens naturally that the people who don’t feel this way don’t end up staying too long with CABBS.

What do you think sets CABBS apart from other yacht carpentry and refit companies operating in the Mediterranean?

That’s easy, like I mentioned before, the quality of the end products and the service the clients receive. I also feel we do very well at thinking a little outside the box and can come up with solutions that may not have been considered.

Looking ahead, what are your ambitions for the next chapter of CABBS? Are there any exciting projects or developments on the horizon?

The next chapter of CABBS, well, who knows really. We are currently involved in our biggest undertaking yet, and I feel very confident we are up to the challenge. While we are still receiving fresh work, I wish to keep growing, find more good people, and improve the working environment for my staff with better facilities and machinery, and take it one day at a time. Eventually, I would like to get to the point where I can have a presence at the larger boat shows, such as the Monaco boat show, but for now, I am just concentrating on what we do best.

After so many years working with some of the world’s most beautiful vessels, what continues to drive your passion for this work?

I guess my passion is just driven by a deep love of boats and of the sea. I have always lived very close to the sea, and it’s a fundamental part of my life. I wouldn’t know what else to do, to be honest. I also find the diversity of each job to be not only challenging but also very satisfying. We are never doing the same thing twice and constantly learning, and I guess that’s why I keep going.

To find out more about CABBS and its services, visit the links below:

CABBS – Carpentry & Boat Building Services

C. d’Asegra 15

Ponent 07011

Palma de Mallorca

Spain

Web: cabbs.es

Tel: +34 971 07 49 65

Email: info@cabbs.es

Instagram: @cabbs_yacht_carpentry

Images © Stuart Pearce